Challenge & Context

Industrial agents require the highest standards to implement IoT solutions to their processes. While many factories have developed and integrated IIoT (Industrial Internet of Things) systems that greatly improve their operations, there are still many industrial agents who don’t really see IIoT as the answer to their daily problems.

The role of Industrial Agents, however, remains undisputed today as it explains how multi-agent systems improve collaborative networks to offer dynamic service changes, customization, improved quality and reliability, and flexible infrastructure. These platforms have the capacity to offer distributed intelligent management and control functions with communication, cooperation and synchronization capabilities, and also provide for the behavior specifications of the smart components of the system.The main reluctances of these agents to take the next step towards industrial digitalization may have the following reasons:

- Lack of trust in digital solutions. The industrial environment requires a maximum robustness and security level. Any problem that might occur could mean remarkable financial and brand reputation losses for the company.

- Resistance to change. These companies usually have a long history in their industries and know which methodologies suit their processes best. They are, therefore, little interested in looking for new solutions when the ones they are using are still working.

- Limited vision. Data-driven management and decision making might not seem that useful without a good digital strategy. In many cases, industrial agents are not really convinced that the implementation of industrial sensors and data analytics are crucial to their future.

- Complex and redundant systems. Most IIoT solutions are proprietary systems that struggle to integrate other tools or systems (e.g. System-of-Systems approach) or be integrated into larger digital ecosystems. For the customer, the obligation to use different interfaces can be difficult.

Nowadays, it is clear that Industry 4.0 has become a requirement for all the industries that wish to remain competitive and scalable in the future, and systems that can ease this adaptation have a great opportunity to break into the market.

Solution

As an IoT engineering company specialized in services analysis of data for the Industry sectors, Spain based Purple Blob, has faced the problem of integrating industrial solutions. In response, they developed SARA. SARA is a FIWARE-based IoT platform designed to fit in industrial environments and operate with maximum efficiency. The main goal of SARA is to offer a centralized system in which many IIoT solutions can coexist, minimizing the effort to integrate devices and digital tools from different suppliers allowing an organized user and device management and enabling the use of shared analytical tools. This centralized system can thus maximize the value of each solution by aggregating the information of the other systems.

Moreover, SARA follows a modular architecture that can implement one or several components depending on customer needs. This allows the implementation of a step-by-step strategy that can prove to the client that a digital approach can actually improve their company.

In addition, SARA offers industrial-grade security and availability that covers both users and information throughout the entire data life cycle. Additionally, the platform is based on Kubernetes, which allows for complete scalability and efficient resource management. Lastly, the FIWARE architecture grants maximum interoperability to use other digital tools along with SARA or to integrate the platform in greater projects.

All these benefits are provided to the users through a web interface that can be accessed via a computer or mobile phone showing all the information that SARA stores on interactive dashboards from which the users can:

- Visualize the reports or the results of the analytical processes that have been applied to the information. They can also filter most visualizations with time lapses, variable filtering, and even query configuration;

- Get alerted under certain circumstances, like the depletion of an oil tank, a smoke detection event, and similar situations;

- Manage the devices, adding, modifying, deleting, and debugging these from the reports and from information messages that components generate along the way when a new report is received;

- Manage the channels and interfaces in which SARA is interconnected with devices and other external systems;

- Manage the users and their permissions.

It is important to notice that SARA allows a comprehensive permission management based on user groups and organizations, so that the administrator can tailor them to suit any kind of environment, for example, different departments in the same company.

How it works

When implementing SARA in a new industrial customer, the first step is to understand their exact challenges. Usually, Purple Blob interviews first the technical department or the managers asking them questions like:

- Which, in your opinion, is the least efficient process in the factory?

- Is there any information that you lack and could be useful for you?

- What are the costliest operations?

- Do you have any plan to change your business model in the future?

Once they have detected one or more areas of improvement for SARA and further industrial solutions, they design a first-approach project whose objective is to show the customer the value and opportunities IIoT systems may grant them. Usually, such a project is heavily focused on the most problematic areas that need heavy and / or fast problem solving and can be carried out directly through the implantation of sensors and alarms on the platform, for example.

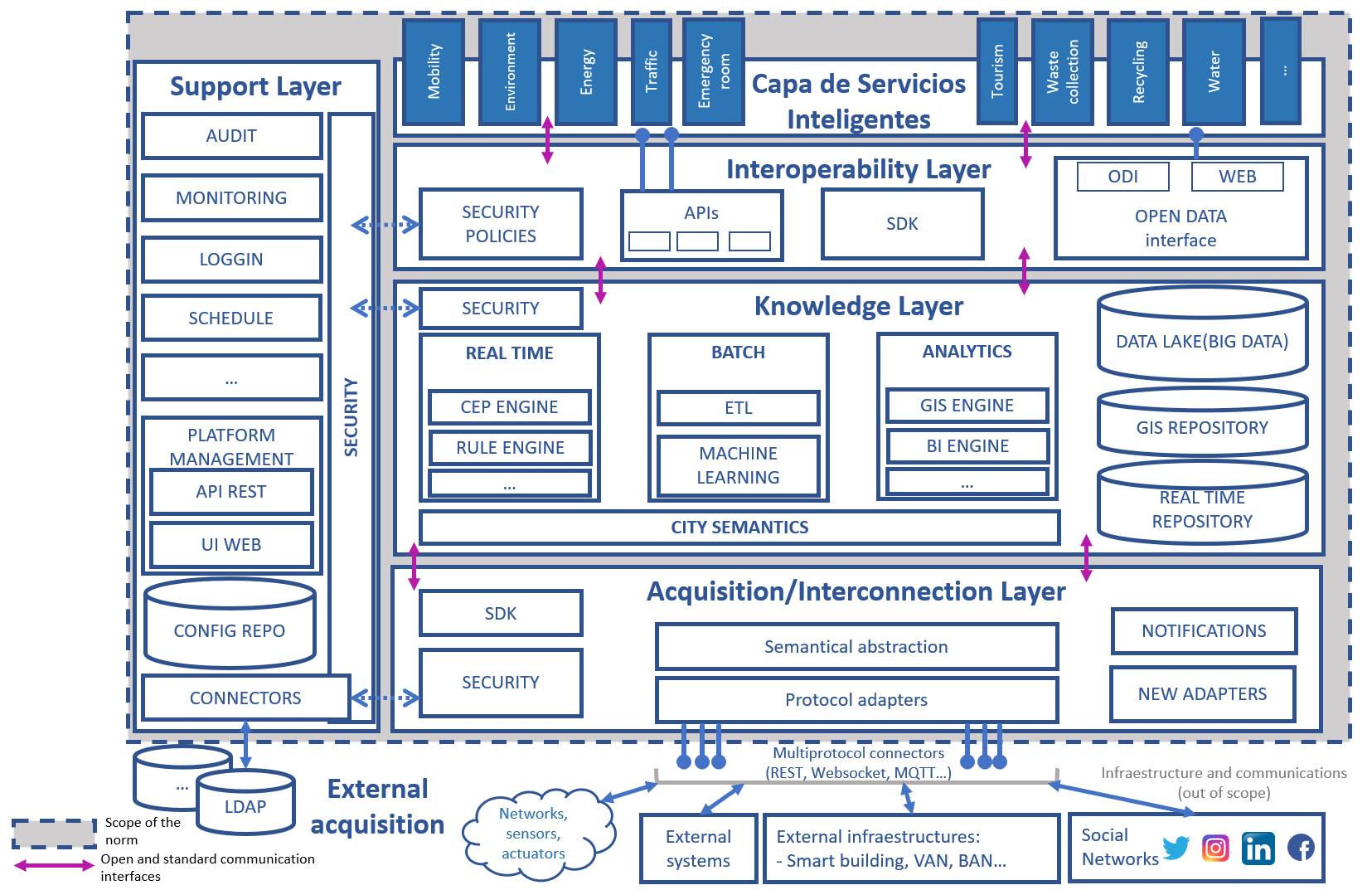

SARA follows the IoT platform architecture proposed by the Spanish agency AENOR with its norm UNE 178104. This norm structures the platform in several layers:

Figure 1 . UNE 178104 IoT platform architecture

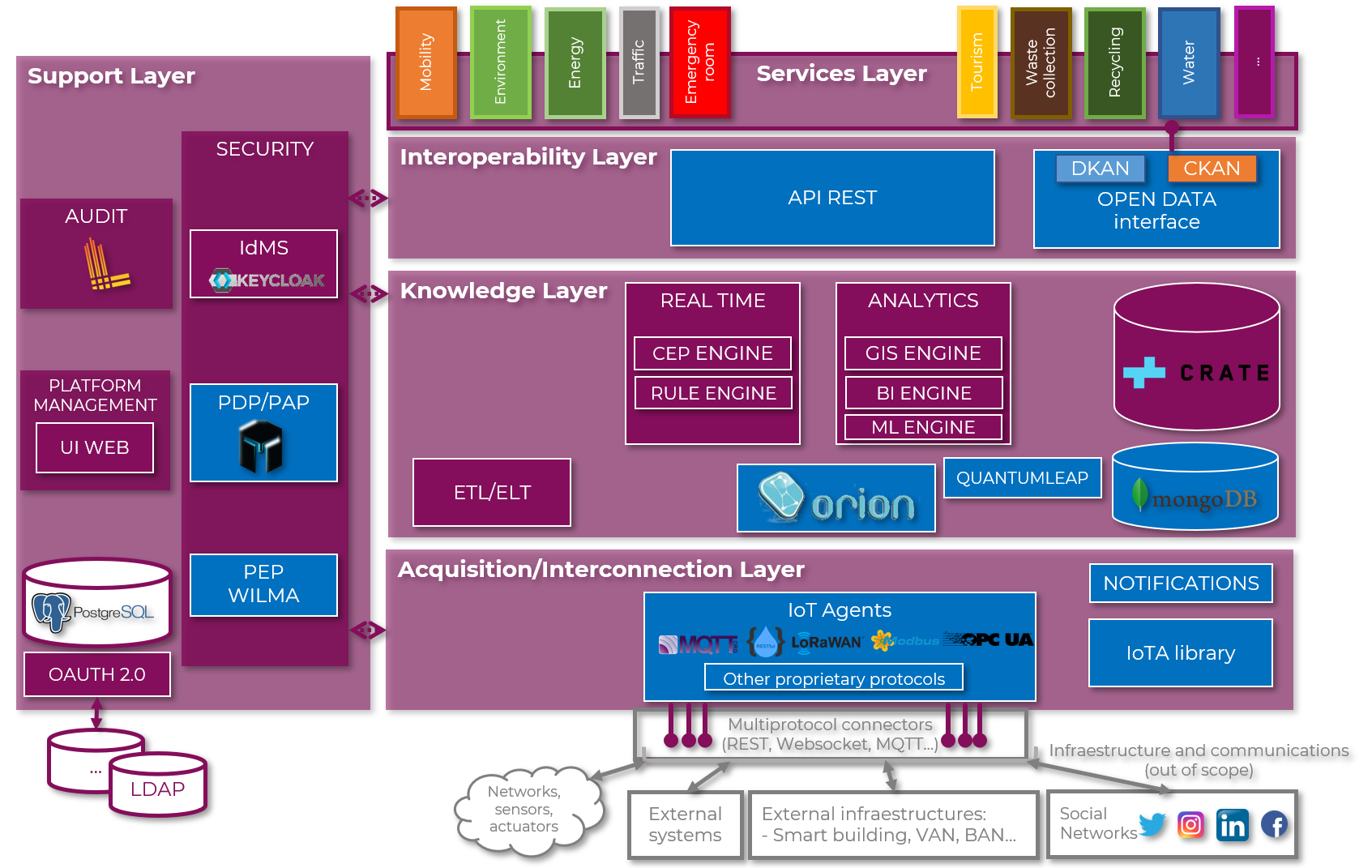

Thanks to the IoT Agents of FIWARE, SARA’s Acquisition/Interconnection Layer can be tailored to the industrial case. Many protocols like MQTT, HTTP API REST, ModBUS, and OPC-UA are supported by default, however, there are many solutions that use proprietary protocols. In these cases, the IoT Agent library helps Purple Blob to quickly develop new IoT Agents for any protocol the system may need.

On the Knowledge Layer, SARA uses the FIWARE Context Broker (core element of the FIWARE platform) to communicate the context information with the rest of the components with a shared NGSIv2 semantic. SARA uses several intelligence and analytic tools connected with CrateDB, the NoSQL database, to generate all the information that is then served to the interoperability and the intelligent services layer.

The first one allows the connection of other systems, mainly through API REST services. The second one is based on a visualization and management web interface that enables the monitorization and control of every service.

Figure 2 . FIWARE Architecture

Last but not least, the support layer provides security and audit capabilities for each layer. This layer can be configured and monitored via the web interface. Users with sufficient permissions can:

- monitor the status of all the components;

- debug the reports and the information along the way through the different layers;

- manage the devices;

- manage organizations, users, and permissions;

- manage and control the different dashboards, editing the queries, visualization panels, and generating new dashboards.

All these functionalities enable a full customization of the platform. One great benefit of SARA is that it normally offers preconfigured services and dashboards, so the user can see the results as soon as the system is up and running.

Benefits & Impact

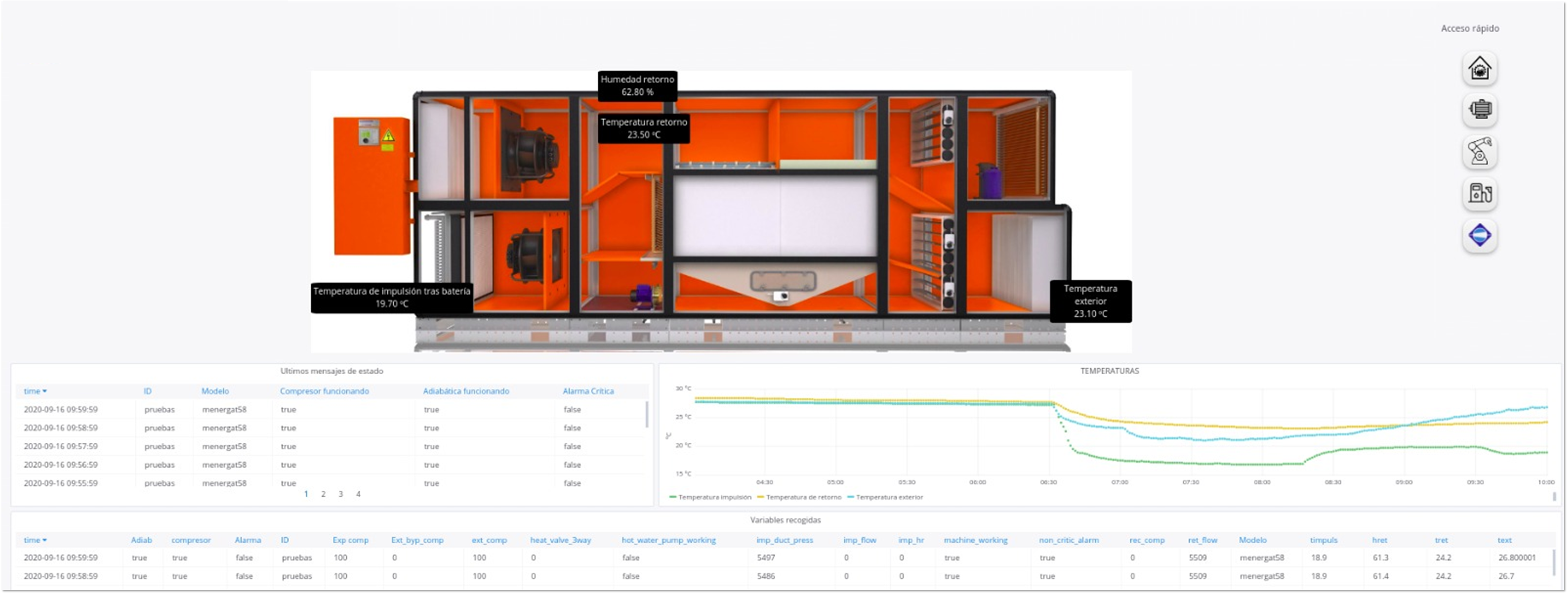

The result of the implementation is a fully operative IoT platform that can be easily accessed and managed from all kinds of devices. So far, SARA has been implemented successfully in many industries and use cases alike:

- Monitorization of industrial machinery for predictive maintenance;

- Asset tracking and logistics, calculating the estimated time of arrival and detecting possible problems on the way;

- Vehicle and passersby tracking through cities and industrial parks, allowing for predictions, pattern detection and occupation alerting;

- GLP deposit monitorization, alerting on low levels and detecting possible failure of the sensors used to monitor the deposits.

In the simplest cases, SARA works fine with the visualization of historical and simple alerts only. In the most complex implementations, predictive analysis and complex event processing is applied to detect patterns and situations that can’t be directly extracted from the bulk data.

Figure 3 . Predictive maintenance dashboard for an industrial dehumidifier

In any case, SARA operates with only the required components, thus having a maximum efficiency. Once proved, its capabilities can be extended with new components and services that can be shown on the same dashboards or on new dashboards specific for the situation.

Added value through FIWARE

The use of components of the FIWARE project offers many advantages. On one hand, the use of the IoT Agent library enables a quick and high-quality development of the IoT Agents. A good example of the power of this library is the integration of a proprietary protocol based on the SMS protocol. Within a few weeks, Purple Blob implemented not only data acquisition but device management capabilities through the FIWARE Context Broker and the Agent.

On the other hand, the use of NGSIv2 semantics and the FIWARE Context Broker grants maximum interoperability to SARA, which eases the integration of the platform with other IoT platforms and Smart City projects.

Lastly, the use of FIWARE components has made it possible to develop an industrial grade IIoT platform that can be adapted to most use cases with maximum security and robustness while allowing Purple Blob to implement sequential step-by-step digitalization strategies.